Plant & Machinery

Pipe Process

Automatic Pipe Cutting & Bevelling Machine

- Tubes are fed to the machine for cutting.

- Total load volume of loading & storage rack is 19 pieces of 0159 tubes with 4 tons’ load capacity.

- Storage rack is designed with a proper incline angle to enable the tube roll downward to kick-in position.

- The kick-in plates are driven by multiple-units of air cylinder, which can kick the tube onto feeding roller table one after another.

- Pipe length fixing is done by AC servo system

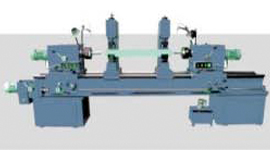

Automatic Double Headed Pipe Boring

-

- Align Clamping mechanism driven by electric motor to control boring depth and high accuracy.

- Dimensional Tolerance of bore space is 0.20 mm.

- Pipes are bored simultaneously to achieve concentricity.

- Pipe size 60 to 167 mm

Automatic Double Headed CO2 MIG Welding

-

- Automatic Welding provides an optimum and consistent quality of weld as compared to manual process with the ease in Nozzle Cleaning and Wire Shearing function automized to achieve the highest quality of weld.

Shaft Process

Shaft Cutting with Bendsaw Blade Machine

-

- Shaft cutting over bendsaw blade machine capacity 20 mm to 150 mm bar.

CNC Shaft Milling with Synchronise Arrangement

-

-

- We achieve and accuracy upto 0.007 mm in Axial float (End play) by grooving the shaft on CNC turning machine which an important parameter for the roller.

-